Welcome to the MSSL Facilities website. Below you will find specifications for the various facilities within the Mechanical engineering group with contact details for each. If this specification page does not provide you with the information you are looking for you can click on the link provided at the top of each facility heading.

Click on the links below to quickly take you to the specific facility you want to look at.

- Vacuum bakeout facility

- Thermal vacuum facility

- Vibration facility

- Cleanroom facility

- Laser & Sputter coating facility

- Westbond wire bonding facility

- Mechanical Engineering Workshop

- Other facilities

Vacuum bakeout Facility [Website]

- Diameter: 390 mm

- Height: 350 mm

- Max temperature: 150°C (Can do 200°C with reconfiguration)

- Base Vacuum pressure: 5 x 10-8 mbar (3.75 x 10-8 torr)

- Temperature accuracy: ± 2°C

- # of thermocouples: 4 chamber + 2 shroud

- RGA: Yes, 1 to 100 Atomic Mass Unit (AMU)

- TQCM: Yes, 15 MHz faraday + controller and logging

- Temperature ramp rate: 0.10 to 5 °C per minute

- Temperature logging: Yes

- Pressure logging: Yes

- Turbo pump: Seiko Seiki STP400 MagLev

- Vent gas: Zero Grade Nitrogen

- Facility cleanliness FED STD 209E class 100

Contact:Alex Rousseau TEL:+44(0)1483 204100

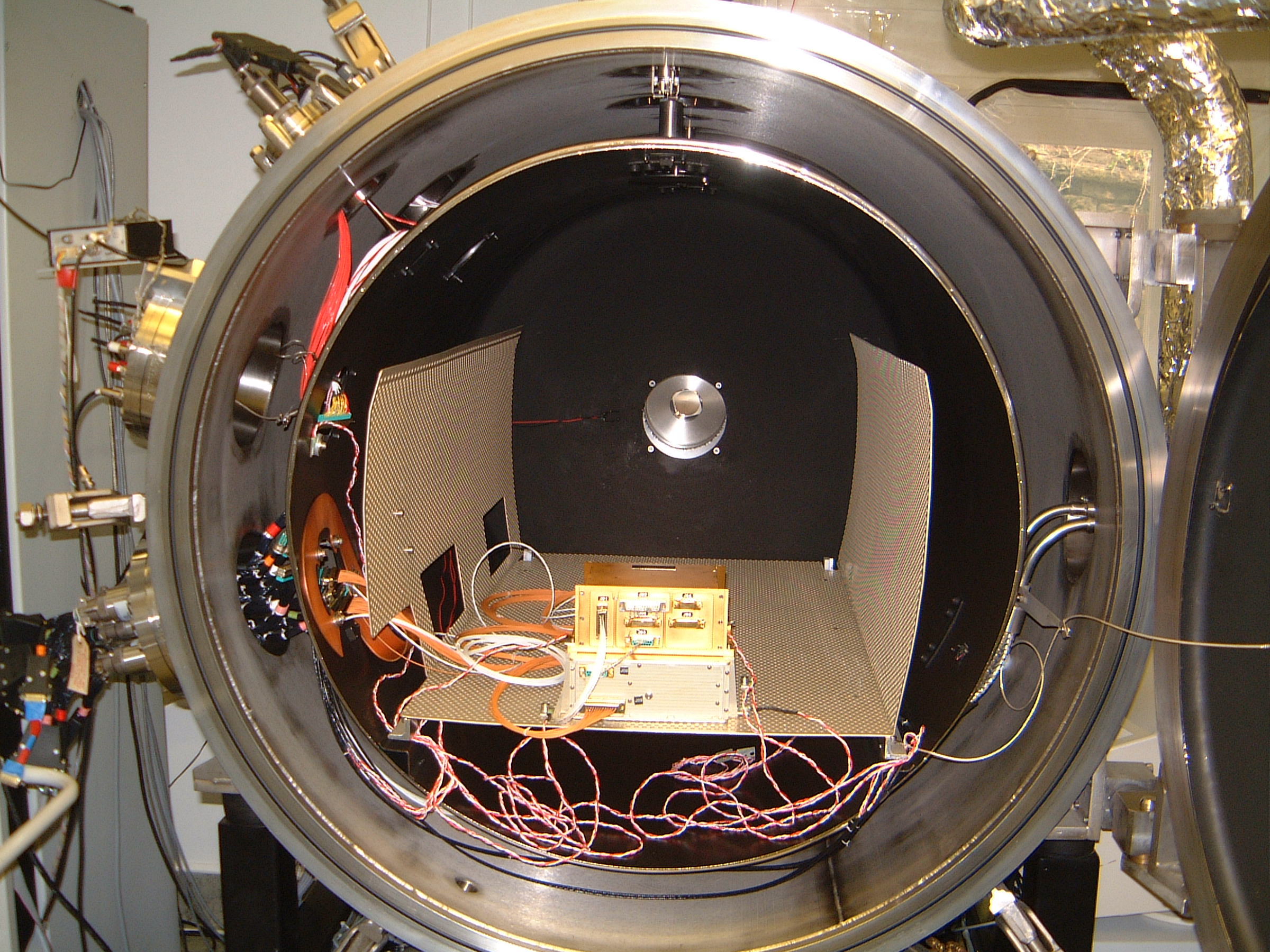

Thermal Vacuum facility [Website]

- Diameter: 1000 mm

- Length: 1400 mm

- Max Temperature: +70°C

- Min Temperature: -45°C

- Base vacuum pressure: 5 x 10-7 mbar (3.75 x 10-7 torr)

- Temperature accuracy: ± 0.5°C

- # of PRT's: up to 25 (normally 6 for chamber + 2 shroud)

- RGA: Yes, 1 to 100 Atomic Mass Unit (AMU)

- TQCM: Not normally but can adapt/reconfigure to suit

- Temperature ramp rate: 0.1 to 5 °C

- Temperature logging: Yes

- Pressure logging: Yes

- Cryo pump Leybold

- Harness feed through Yes, D-sub 9 to 50 way (can adapt for other connections)

- # of ports for harnessing: 3

- Facility cleanliness: FED STD 209E Class 1000

- Vent gas: Zero Grade Nitrogen

Contact:Alex Rousseau TEL:+44(0)1483 204100

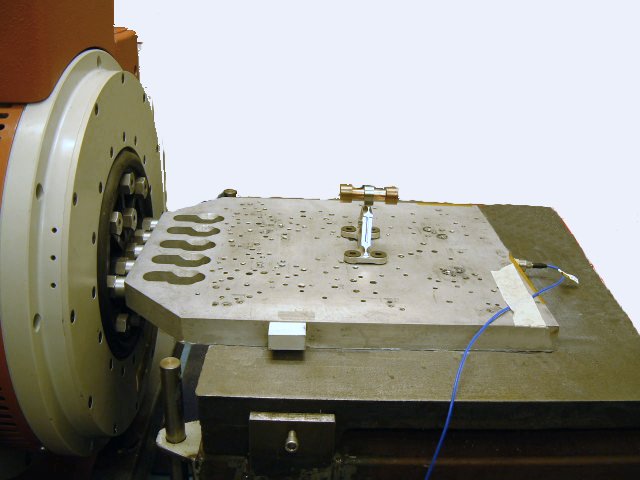

Vibration Facility [Website]

- Make Ling Dynamics V762

- Max mass 5-10 Kg.

- Max size of instrument: 350 mm x 400 mm

- Max Thrust: 3800 N (acting on test specimen and adapter plate)

- # of channels: 4 ( 1 for control, 3 for monitoring)

- Accelerometers: Endevco 2224C and Endevco 2226C

- Calibration: Complete facility independently tested and calibrated

- # of axis measurements 3

- Facility cleanliness: FED STD 209E Class 30 000

- Controller information

- Ling Dynamics DVC 4000 Mk 6 Sine dual resonance dwell vibration controller

Sine Specifications

- Frequency range: 1 Hz to 4 KHz (sine)

- Frequency breakpoints: 16 (controlling either displacement, velocity or acceleration)

- Sweep: Logarithmic or linear

- Control modes: Single channel, average, extremal, notch or multi channel

- Resonance dwell: Two channel amplitude control

- Random Specifications:

- Frequency range: 125, 250, 500, 1000, 2000, 4000 Hz

- Control modes: Average or extremal control

- Breakpoints: 125 max. per profile

- Level scheduling: 8 test levels/durations definable

Transient specifications

- Pulse shapes: Halfsine, Initial peak sawtooth, terminal peak sawtooth, triangular, trapezoidal, rectangular and user defined

- Optimise on time, velocity or displacement

- 400 point user defined pulse

- Four channel signal averaging

Contact:Berend Winter TEL:+44(0)1483 204100

Cleanroom Facility [Website]

- Airborne particulate class: FED STD 209D Class 100 with local class 10 areas

- Surface particulate level: MIL-STD 1246C level 100/150

- Background Non Volatile Residue: MIL-STD 1246C level A (0.1 mg/m2 )

- Background airborne molecular contamination levels of 1.8 Å to 2.0 Å /month

- Temperature and humidity controlled to 45 % RH and 18 °C

- Cleanroom facility: 2, one dark cleanroom for optical alignment, assembly, integration and testing and one "white" cleanroom for general cleanroom work not requiring light proofing.

- Cleanroom facilities are serviced and validated twice a year by independent contractors

- In addition to HEPA filters the cleanroom is fitted with molecular adsorption filters

- Cleanroom clothing and training provided to users and visitors

- Contamination control/management problem solving provided

- Tape lift sampling provided

- Airborne Molecular Contamination (AMC) monitoring (realtime) and logging

- Non Volatile Residue (NVR) swab sampling used

- Real-time airborne particulate sampling and logging

- Filtered Nitrogen and Argon house supply

- TS4 Dynascope - Stereo microscope with QC2000 digital readout, encoders repeatable to ± 2 microns

Contact:Alex Rousseau TEL:+44(0)1483 204100

Laser and Sputter coating facility [Website]

- Nd-YAG - CW 15W, Q-switched peak power 30 kW

- Focussed Beam Diameter - 10 to 100 microns (therefore we can create a slot approx 10 µm wide or greater)

- Computer controlled co-ordinate table 1 µm accuracy and 150 mm travel

Applications:

- Precision machining of designs (etched lines) in thin films on insulating substrates (Glass, Ceramics, etc.)

- Machining of sheet metal (e.g. Phosphor Bronze, Stainless Steel) up to a maximum thickness of 0.5 mm

Sputter Coating

Choice of film material:

- Aluminium

- Copper

- Gold

- Chrome

- Insulators e.g. SiO2

- others can be installed

- all targets are 100 mm diameter

Substrate dimensions:

- Thickness up to 30 mm

- For optimum coating uniformity substrates of up to 60 mm diameter may be accomodated.

- It is possible to coat larger parts, up to 300 mm diameter.

Contact: Dave Walton TEL:+44(0)1483 204100

- This tool allows small scale interconnects to be placed between metal pads.

- Ultrasonically bonds the connecting wires to the pads.

- Wire may be gold or aluminium, diameter range 18-100 µm.

- Used in the manufacture of readout anodes (for Microchannel plate detectors) to bridge insulating gaps.

Contact: Dave Walton TEL:+44(0)1483 204100

Mechanical Workshop facility [Website]

- CNC and traditional milling machines capable of machining complex geometries utilising CAM software

- CNC and traditional Lathes capable of turning parts from 1 mm up to 150 mm diameter. Larger diameters can be accommodated

- Spark eroding machining facility capable machining complex components

- TIG/ARC welding facility

- Gas welding facilities

- Alocrom 1200 coating facilities

- Standard pedestal vertical drilling facilities

- Sheet bending and rolling facilities

- Electric oven 20°C to 600°C, component size 300 mm x 300 mm max.

- Furnace oven 20°C to 1200°C, component size 150 mm x 150 mm max.

Contact:Tony Murrell TEL:+44(0)1483 204100

Ultrasonic cleaning facilities W150 mm x L300 mm x H300 mm.

Contact:Alex Rousseau TEL:+44(0)1483 204100

©MSSL Created by Alex Rousseau last modified: July 6, 2004 11:24